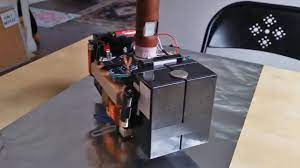

An Electro Magnetic Hammer, also known as a magnetic forming hammer or electro-hydraulic hammer, is a specialized device used to shape and deform metal workpieces.

Unlike traditional mechanical hammers, Electro Magnetic Hammers utilize electromagnetic forces to generate precise and controlled impacts on metal surfaces.

We render our maximum efforts to fulfil customer requirement in achieving best quality with best competitive price.

Metal forming processes are critical in various industries, where precision and efficiency are key factors. Electro Magnetic Hammers have emerged as innovative solutions for achieving accurate metal forming with less material waste and improved productivity. This article delves into the functionalities, benefits, applications, and innovations of Electro Magnetic Hammers in the world of metal forming.

The operation of an Electro Magnetic Hammer involves the following key steps:

Step 1 : Electromagnetic Coil: The hammer is equipped with an electromagnetic coil, typically made of copper, wrapped around a metal core.

Step 2 : Electric Current: When an electric current is passed through the coil, it generates a magnetic field around the core.

Step 3 : Magnetic Force: The magnetic field induces a strong magnetic force in the core, which is then transferred to a specially designed metal forming tool.

Step 4 : Rapid Impact: As the magnetic force intensifies, it rapidly propels the forming tool towards the metal workpiece, creating a powerful impact.

Step 5 : Metal Deformation: The impact causes the metal workpiece to deform and take the desired shape according to the forming tool’s contour.

Step 6 : Controlled Repetition: The process can be repeated multiple times with precise control over the impact force and frequency to achieve the desired metal forming results.

We Are Here To Help You 7 Days A Week And Respond Within 24 Hours. Plus, You Can Find the Most Answers To Your Questions.

We are working as a renowned Spray Dryer, Flash Dryer, Spin Flash Dryer, Evaporator, Fluid Bed Dryer, Blowers, Feeding Systems, Hot Air Generator manufacturer, exporter, supplier and service provider.

Plot No. 5/1 B, Panchrantra Industrial Estate, Ramol - Vatva Over Brdge, Phase - 1, Vatva G.I.D.C, Vatva, A'bad

info@drytechengg.com

+91 98986 82370

WhatsApp us